My Role

As part of the industrial design team my contribution included research, ideation, and sketching as well as CAD and animation work.

The team

Alex Whitman, Goutham Thirumalesh, Shuning Fan, Yan Lyu, Suwenjing Li, Yuxin Miao, Nathan Duderstadt, Xiaojing Li, Jungwen Zhang, Esther Holiday, Yimemg Sun, Xinyu Wu, Guanzhi Kou, Amir Ahmadi, Yoojeong Chol.

Discover

Our client

Trane® is a world leader in air conditioning systems and services. They provide innovative solutions that optimize indoor environments through a broad portfolio of energy-efficient systems.

brief

Re-design Trane's small commercial space thermostat, Pivot. The redesign must mach that of the Leaf AirFi Family, created by the sister SCADPro team. Taking into account Trane's sustainability and climate solutions, the thermostat must lead in 2022 and last into 2030's.

The teardown

In order to get familiar with the Pivot thermostat, the team did a complete teardown of the outer and internals of the unit provided by our client. This enabled us to understand how the thermostat works and what our boundaries were when designing.

Define

Our Research

Through primary and secondary research methods which included, surveys and interviews, we were able to identify our stakeholders as well as key issues and opportunities for innovation.

All of our data points led to the creation of a complete framework that set the path for the industrial design team.

Market Research

Johnson Controls GLAS

Translucent OLED Screen, first of its kind.

Google Nest

Smart and self adjusting. Saves energy and detects people.

Ecobee

Additional small sensor for accurate readings.

.png)

Honeywell

Additional small sensor for accurate readings.

The future thermostat is a smart system

it is Simple

“The only two buttons I really push is up or down.

Those are the only two that I ever use.”

40 yr male occupants Washington, DC

it is Intuitive

“I think the better designs are the ones with fewer options, things that are organized in a very intuitive way.”

35 yr male workshop owner Atlanta, GA

it is Efficient

“The most cost-efficient brand is not wasting electricity on my heating and air conditioning.”

38 yr male Thermostat Contractor Savannah, GA

Develop

ideation

Concept Development

CAD EXPLORATION

Physical Prototyping

Once a direction was chosen, the industrial design team relied heavily in physical prototyping and 3D printing to validate our findings and make fine adjustments to certain details.

The team was able to fit all the components inside the re designed shell and prototype a working screen with a raspberry pi.

Technical Drawings

UX Team

While the industrial design team worked on the outer shell and internal structure, the UX team developed and constructed the interface that would go along with the design.

The UX team was also in charge of conducting user tests.

deliver

Meet the Next Gen Pivot thermostat.

The project resulted in a modern and easy to use design which also reflects Trane's identity and goals moving into the future.

-

Simple look

-

Screen oriented

-

Trane identity

vents

Ventilation holes vary in size, fade across the device and wrap around the large radii. This turns an essential engineering requirement into a design feature.

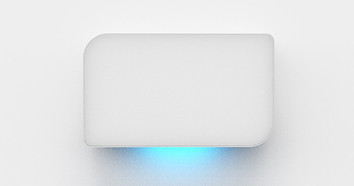

Curves

The curvature from the side, sweeps down away from the wall, adds dynamism and also serves to enhance the lighting along the bottom.

Profile

Clean white front with rounded corners in the shape reminiscent of the Leaf Airfi created by out sister SCADpro project.

Light

In the shadow cast by the overhang, it’s easy to see the splash of LED light, that pop of color, from a distance. Different colors indicate the mode of the thermostat.

iNTERNALS

color and Materials

Speckled Grey

Bioplastic black

Antimicrobial

.png)

.png)

User Interface

conclusion

Being a part of this collaboration with Trane Technologies made me learn and grow as a young professional. I had the incredible opportunity of working in a diverse team full of people with different disciplines. It was important that both UX and ID teams stayed connected throughout the whole process in order to deliver. This project gave us the opportunity to take a deep dive in electronics and design based on engineering requirements. Based on what we learned and researched we were able to make conscious and critical design choices to create a better overall experience for the user.